News

Vietnam Ex-import Insight

Understanding fumigation in export, import cargo

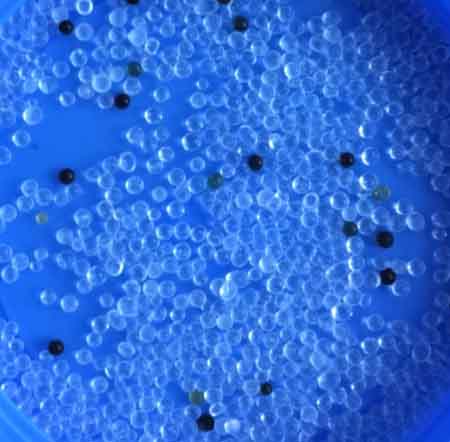

A fumigant is a chemical vapor or gas that, when released, penetrates objects or enclosed areas in concentrations that are lethal to pest organism. This definition excludes aerosols, which are particles suspended in the air, often referred to as smokes, fogs or mists.

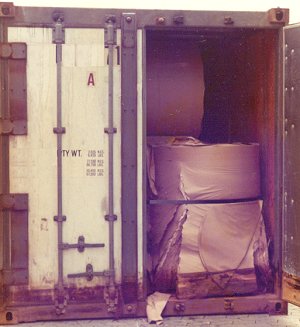

During the sea voyage due to temperature and climatic changes the condensation inside the container will be formed and will damage the cargo. Whoever has opened a shipping container only to find his valuable cargo rusted, moldy and dripping with water can readily appreciate the dangers of moisture in container transports. Most cases of moisture damage are far less severe peeling labels, spotted surfaces or soggy packaging-, but are none the less unacceptable.

Logistics and Packaging World

How To Choose The Right Type Of Tenso Strapping For The Job

Products of varying sizes, shapes and weight have to be safely secured whilst they are being transported.

The Tenso range of strapping supplies and accessories provides a solution for all the load securement requirements relative to all industrial packaging and strapping applications.

There are many applications for the wide range of Tenso strapping products. From bricks to bamboo, from timber to trusses and everything in between.

6 easy ways to save money on your packaging

Have you ever thought about some of the ways that you could find some hidden cost savings potential in packaging? Ten years ago, it wasn’t a high priority. However, as transportation and warehousing costs have continued to steadily rise, companies realized that packaging offered a fresh opportunity to cut costs.